Stop Losing Money: Top Insulation Solutions for Crawl Space Ducts

Why Insulating Ductwork in Crawl Space is Costing You Money

Insulating ductwork in crawl space is essential for preventing energy loss and reducing operating costs. Here's what you need to know:

Top Insulation Solutions:

- Fiberglass Duct Wrap - Most cost-effective, R-6 to R-8 rating

- Rigid Foam Board - Higher R-value per inch, moisture resistant

- Spray Foam - Best air sealing, professional application recommended

Key Steps:

- Seal air leaks first with mastic sealant

- Choose proper R-value (R-8 for unconditioned spaces)

- Wrap ducts completely without compressing insulation

- Secure with UL 181 foil tape

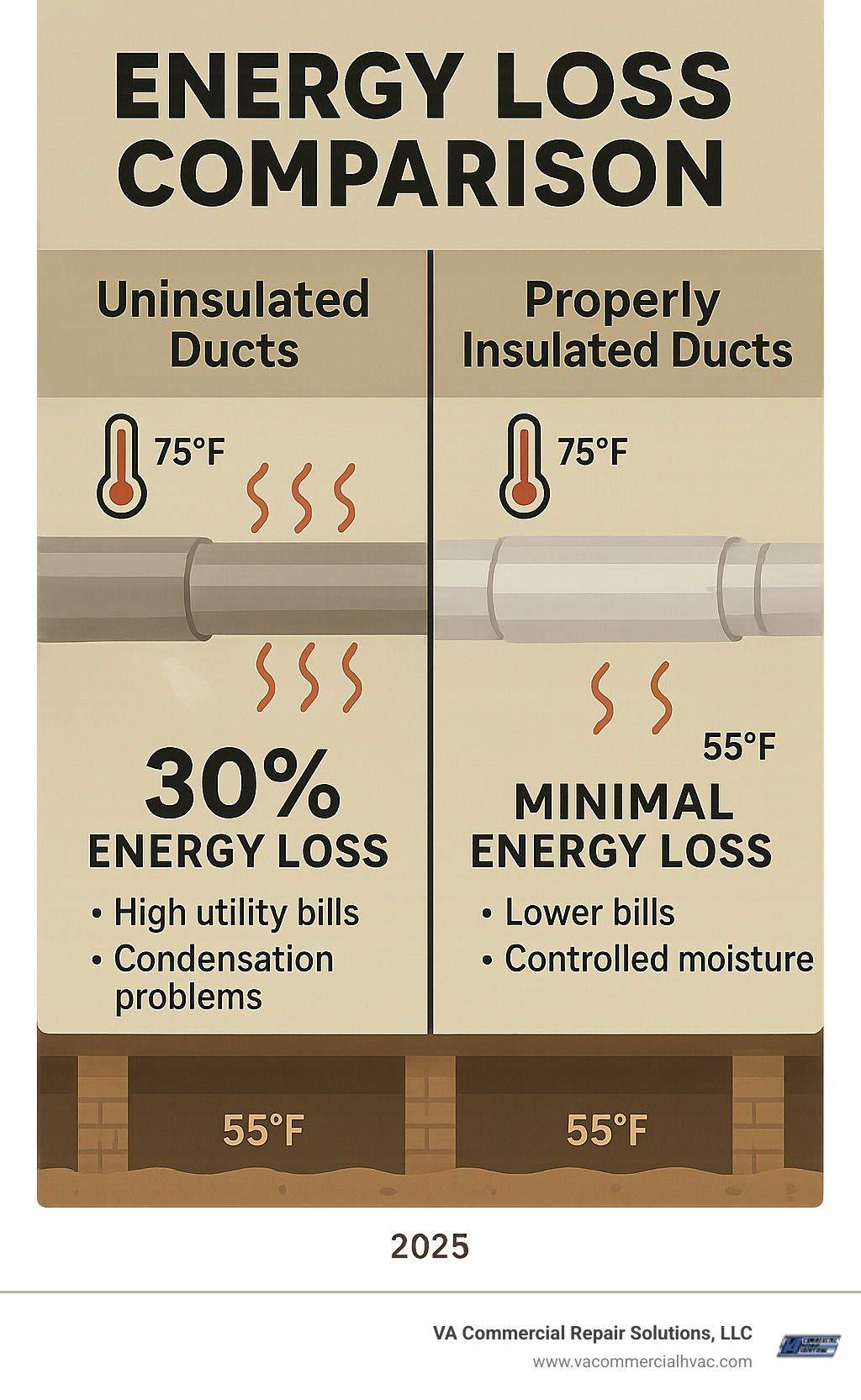

If you're running a restaurant or facility in Central Virginia, uninsulated crawl space ducts are silently draining your budget. The Department of Energy reports that uninsulated ducts can lose more than 30% of their heating or cooling capacity - that's money flowing straight out of your building every month.

You've probably noticed the signs: rooms that never reach the right temperature, sky-high energy bills, or that musty smell that won't go away. Close to 25% of the energy you use to heat and cool your facility disappears through leaky ductwork in unconditioned spaces like crawl spaces.

The good news? This is one of the most cost-effective improvements you can make to your building's efficiency.

I'm Gregg Kell from VA Commercial Repair Solutions, and I've helped countless facility managers in Central Virginia solve their insulating ductwork in crawl space challenges over the years. From restaurants losing money on cooling costs to offices with uncomfortable dining areas, proper duct insulation typically pays for itself within the first year through reduced energy bills.

Why Your Crawl Space Ducts Are a Hidden Energy Drain

Picture this: you're paying to heat or cool your business, but a good chunk of that perfectly conditioned air is escaping into your crawl space before it ever reaches your customers and employees. It's like having a hole in your wallet that just keeps getting bigger every month.

When ductwork runs through an unconditioned crawl space, you're essentially fighting a losing battle against the elements. That energy waste is real – and it's costing you more than you might think. The Department of Energy reports that leaky ducts can account for significant energy loss , sometimes up to 30% of your heating and cooling capacity. That's money disappearing into thin air, literally.

Your high utility bills are just the beginning. When your HVAC system has to work overtime to compensate for all that lost air, it's putting serious HVAC strain on your equipment. Think of it like running a marathon while carrying a heavy backpack – eventually, something's going to give out. You can find more info about evaluating your system to see if yours is working harder than it should.

But here's where things get really problematic. Uninsulated ducts create the perfect storm for condensation issues. When cold air from your AC travels through warm, humid ducts in summer, or when warm air meets cold crawl space conditions in winter, moisture builds up on the duct surfaces. This "duct sweating" creates a damp environment that's practically an invitation for mold growth .

Once mold takes hold, you're dealing with poor indoor air quality that can affect everyone in your building. Those musty smells and stuffy conditions aren't just unpleasant – they can impact your employees' health and your customers' experience.

The Critical First Step: Sealing Air Leaks

Before we even talk about insulating ductwork in crawl space , we need to address the elephant in the room: duct leaks . Adding insulation to leaky ducts is like putting a sweater on someone who's bleeding – you're missing the real problem.

Conditioned air loss through unsealed ducts is a massive energy drain. Even well-installed systems can have around 3% leakage, but older installations from the 1990s or earlier? We're talking 15-20% of your air just vanishing into the crawl space.

The solution is proper sealing with mastic sealant and foil tape . Mastic is like a thick, paintable putty that dries to form an incredibly durable seal. It won't crack, shrink, or fall off over time – unlike some other "solutions" we've seen fail spectacularly.

For smaller gaps and sealing joints , UL 181-rated foil tape is your friend. Pay special attention to sealing connections where duct sections meet, where ducts connect to your HVAC unit, and especially at registers and grilles. These spots are notorious for developing leaks.

Here's a pro tip that might save you from a costly mistake: why you should never use standard duct tape. Despite its name, regular duct tape is terrible for actual ductwork. It degrades quickly, loses its stick, and basically turns into expensive confetti in your crawl space. We've seen too many "quick fixes" that turned into ongoing problems.

Key Benefits of Insulating Your Ductwork

Once your ducts are properly sealed, the benefits of insulation become crystal clear. You'll see energy savings almost immediately as your HVAC system doesn't have to work as hard to maintain comfortable temperatures. We're talking real money here – hundreds of dollars annually that stays in your pocket instead of disappearing into your crawl space.

Improved comfort is another game-changer. No more cold spots in winter or stuffy areas in summer. Your employees will be happier, your customers more comfortable, and your thermostat will actually mean something again.

Moisture control is huge for protecting your building's structure and maintaining a healthy environment. Insulation prevents condensation on duct surfaces, eliminating the conditions that mold and mildew love. This means cleaner air and fewer headaches down the road.

Your HVAC equipment will thank you too. When your system isn't constantly overworking, it experiences less wear and tear, leading to a longer HVAC lifespan . That expensive equipment you invested in? It'll last longer and perform better.

Finally, better air quality and reduced noise from your HVAC system create a more pleasant environment for everyone. Your ducts won't be rattling and banging as much, and you won't be circulating pollutants from the crawl space throughout your building.

Top Insulation Materials for Crawl Space Ductwork

When it comes to insulating ductwork in crawl space , choosing the right material can make the difference between a job that pays for itself quickly and one that leaves you wondering where your money went. Each option offers its own balance of upfront cost, how easy it is to work with, and how well it actually insulates your ducts.

The effectiveness of any insulation is measured by its R-value – think of it as the material's resistance to heat flow. The higher the R-value, the better it insulates. For ducts running through unconditioned spaces like crawl spaces, most building codes call for R-8 insulation as the minimum. Of course, we always recommend checking with your local building authorities in Charlottesville, Harrisonburg, or wherever you're located in Virginia, since requirements can vary by locality.

Here's how the three most common materials stack up:

| Material | Cost | DIY-Friendliness | Typical R-Value | Notes |

|---|---|---|---|---|

| Fiberglass Duct Wrap | Most affordable | Easy for most people | R-6 to R-8 | Widely available, requires safety gear |

| Rigid Foam Board | Moderate | Moderate skill needed | R-5 to R-6 per inch | Excellent moisture resistance |

| Spray Foam | Most expensive | Professional installation | R-6 to R-7 per inch | Best air sealing properties |

Fiberglass Duct Wrap

This is the workhorse of duct insulation – the material you'll find in most supply stores and the one most facility managers choose for their first insulating ductwork in crawl space project. Fiberglass duct wrap is popular for good reason: it's cost-effective , relatively easy to work with, and gets the job done well.

Most fiberglass duct wrap comes with a foil-faced vapor barrier on one side, which is crucial for preventing moisture problems. You'll typically find it in convenient rolls, making it easy to transport and work with in tight crawl spaces. The material is flexible enough to wrap around rectangular and round ducts without too much fuss.

However, there's an important safety consideration. Proper handling and PPE are absolutely required when working with fiberglass. Those tiny glass fibers can irritate your skin, eyes, and respiratory system. Always wear long sleeves, gloves, safety glasses, and a dust mask. Trust me, skipping the safety gear will make for a very uncomfortable day.

Rigid Foam Board

If you're looking for higher R-value per inch and superior moisture resistance , rigid foam board might be your answer. This material is particularly effective in humid crawl spaces where moisture control is a primary concern. It's also incredibly durable – once properly installed, it can last for decades without degrading.

The main challenge with rigid foam board is the installation process. Cutting and fitting the boards around ducts requires more skill and patience than simply wrapping with fiberglass. You'll need to carefully measure each section, cut the foam to fit, and then seal all seams with specialized tape to maintain the vapor barrier.

While it requires more upfront effort, many facility managers find that the long-term performance and moisture resistance make it worth the extra work, especially in particularly humid or problematic crawl spaces.

Spray Foam Insulation

For the ultimate in performance, spray foam insulation offers excellent air sealing properties and the ability to fill irregular gaps that other materials might miss. It expands to fill every nook and cranny, creating a seamless insulation barrier that's hard to beat.

However, we typically recommend professional application for spray foam, especially in commercial settings. The equipment is expensive, the chemicals require careful handling, and getting the right thickness and coverage takes experience. While the higher cost can be a deterrent, the superior performance often justifies the investment for businesses with significant energy costs.

You'll also need to choose between closed-cell and open-cell spray foam. Closed-cell offers better insulation value and moisture resistance, while open-cell is more affordable but less effective in humid conditions. For most crawl space applications, closed-cell is the better choice.

Top Insulation Materials for Crawl Space Ductwork

When it comes to insulating ductwork in crawl space , choosing the right material is crucial. Each option offers a different balance of cost, ease of installation, and thermal performance. Insulation effectiveness is measured by its R-value , which indicates its resistance to heat flow. A higher R-value means better insulating power. For ducts in unconditioned spaces like crawl spaces, the Residential Building Code often calls for an R-8 insulation rating, though we always recommend checking with your local building codes in Charlottesville, Harrisonburg, or other Virginia localities for specific requirements.

Here's a comparison of the most common materials we encounter:

| Material | Cost (General) | DIY-Friendliness (General) | Typical R-Value (per inch or total) | Notes |

|---|---|---|---|---|

| Fiberglass Duct Wrap | Low to Moderate | High | R-6 to R-8 total | Most common choice; includes foil vapor barrier; widely available |

| Rigid Foam Board | Moderate to High | Moderate | R-3 to R-6 per inch | Higher R-value per inch; moisture resistant; requires cutting and fitting |

| Spray Foam Insulation | High | Low (Professional recommended) | R-3 to R-7 per inch | Excellent air sealing; fills gaps; professional application preferred |

Fiberglass Duct Wrap

Fiberglass duct wrap remains the most popular choice for insulating ductwork in crawl space projects, and for good reason. It's cost-effective, readily available at most home improvement stores, and comes with a foil-faced vapor barrier that helps prevent condensation and moisture problems.

This insulation typically comes in convenient rolls, making it relatively easy to handle and install around both round and rectangular ducts. The foil backing serves double duty - it acts as a vapor barrier to prevent moisture buildup and provides a clean surface for sealing seams with foil tape.

When working with fiberglass insulation, proper handling is essential. Always wear personal protective equipment (PPE) including long sleeves, safety glasses, a dust mask, and work gloves. The tiny glass fibers can irritate skin and respiratory systems, so taking these precautions isn't optional - it's necessary for your safety and comfort.

Rigid Foam Board

For those seeking higher R-value per inch , rigid foam board insulation offers excellent thermal performance. This material is particularly moisture resistant and incredibly durable, making it ideal for the sometimes harsh conditions found in crawl spaces.

The main challenge with rigid foam board is the installation process. You'll need to carefully measure and cut pieces to fit around your ductwork, which can be time-consuming, especially around complex duct configurations. Cutting and fitting requires patience and precision, but the results are worth it.

Once installed, all seams must be sealed with specialized tape designed for foam board applications. This creates a continuous thermal barrier that can significantly outperform other insulation types in terms of long-term energy savings.

Spray Foam Insulation

Spray foam insulation represents the premium option for duct insulation, offering excellent air sealing properties that other materials simply can't match. It expands to fill irregular gaps and spaces, creating a seamless barrier around your ductwork.

The biggest advantage of spray foam is its ability to address air leaks and insulation in one application. It adheres directly to duct surfaces and surrounding structures, eliminating the gaps that can reduce the effectiveness of other insulation types.

However, spray foam typically requires professional application due to the specialized equipment needed and the importance of proper mixing and application techniques. The higher cost reflects both the material expense and the skilled labor required for installation.

When considering spray foam, you'll encounter two main types: closed-cell and open-cell foam. Closed-cell foam offers higher R-values and better moisture resistance, making it the preferred choice for crawl space applications where humidity can be a concern.

The choice between these materials often comes down to your budget, DIY comfort level, and specific crawl space conditions. In my experience helping Central Virginia businesses, fiberglass duct wrap handles most situations effectively, while spray foam makes sense for complex installations or when you're dealing with significant air leakage issues.