Commercial Electric Transformers Charlottesville

Industrial Electric Transformers Harrisonburg VA

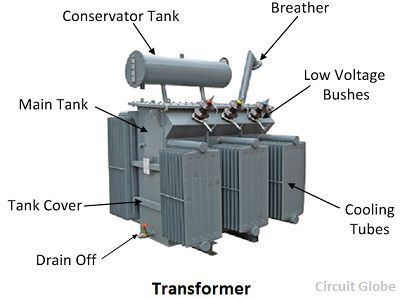

Commercial and Industrial Electric Transformers are essential components in many modern industrial and commercial business environments in Charlottesville & Harrisonburg VA. These devices are responsible for transmitting and distributing electrical energy efficiently while adapting voltage levels to suit various applications. From powering heavy machinery to illuminating large-scale commercial spaces, transformers play a crucial role in ensuring a reliable and safe supply of energy. This web page provides a detailed examination of the types, applications, and maintenance of Commercial and Industrial Electric Transformers.

What Are Commercial and Industrial Transformers?

Commercial and industrial transformers are electrical devices that transfer energy between two or more circuits through the principle of electromagnetic induction. Their primary function is to either increase (step-up) or decrease (step-down) voltage levels to match the requirements of electrical equipment or distribution networks.

Key Characteristics

1.

Transformers

are designed to achieve energy conversion with minimal energy losses.

2. Durability

Commercial Electric Transformers are built to withstand extreme operating conditions, ensuring reliability over long periods.

3.

Customizability

Transformers can be tailored to meet specific power requirements and adapt to unique environmental conditions.

Types of Transformers:

Several types of transformers are used in commercial and industrial settings, each designed to fulfill specific purposes.

1.

Distribution Transformers

Distribution transformers deliver electricity from power grids to end-use applications. They typically operate within a voltage range of 2.4 kV to 33 kV. These transformers are commonly found in settings such as office buildings, residential complexes, and light manufacturing facilities.

2.

Power Transformers

Power transformers are designed to handle high-voltage transmission lines in utility and industrial systems. They usually operate at voltage levels exceeding 33 kV and are commonly used in substations and large industrial plants.

3.

Autotransformers

Autotransformers are specialized transformers that adjust voltage levels in long-distance transmission networks. They are known for their compact design and high efficiency. Autotransformers are often used in industrial equipment that require specific voltage inputs.

4.

Dry-Type Transformers

Dry-type transformers are designed for environments where fire safety is a priority. Unlike their liquid-filled counterparts, these transformers are encased in non-flammable materials instead of relying on liquid coolants. They are commonly used in commercial buildings, hospitals, and data centers.

5.

Liquid-Filled Transformers

Liquid-filled transformers are ideal for outdoor installations and high-power applications. These transformers use oil or other liquid coolants to regulate their temperature. They are frequently used in manufacturing facilities and power generation plants.

Transformers are integral to a wide range of commercial and industrial applications.

Their versatility enables them to power various operations effectively.

1.

Commercial Sector

In the commercial sector, transformers power HVAC systems in malls and office buildings, support electrical infrastructure in hospitals and educational institutions, and provide lighting for large-scale venues such as stadiums and convention centers.

2.

Industrial Sector

In the industrial sector, transformers supply energy to heavy machinery in factories, ensure stable electricity for high-demand equipment such as furnaces and compressors, and facilitate renewable energy projects like wind and solar farms.

Key Considerations When Choosing a Transformer:

Selecting the right transformer for your commercial or industrial application requires careful consideration of several important factors:

1. Load Capacity

It is essential to assess the maximum load that the transformer will need to handle to ensure it meets operational demands.

2.

Efficiency

High-efficiency transformers are preferable as they help reduce energy losses and lower operational costs over time.

3.

Environmental Factors

It is important to take into account temperature extremes, humidity levels, and potential exposure to corrosive elements when choosing a transformer.

4.

Compliance

Transformers should comply with industry standards such as ANSI, IEEE, and IEC to ensure quality and safety.

5.

Safety Features Look for transformers equipped with advanced cooling systems, fire-resistant designs, and overload protection mechanisms to enhance reliability and safety.

Electric Transformer Maintenance and Best Practices

Regular maintenance is critical to extending the lifespan and optimizing the efficiency of transformers. The following best practices can help ensure the long-term performance of transformers:

1. Routine Inspections

Conduct regular inspections to check for overheating, oil levels, and any visible signs of wear and tear.

2.

Cleaning and Cooling

Keep transformers clean and free of dirt and debris to maintain efficient cooling performance.

3.

Testing and Diagnostics

Perform periodic electrical tests to detect potential issues before they escalate into major problems.

4.

Oil Analysis

For liquid-filled transformers, conduct oil testing to identify contaminants or signs of degradation in the insulating oil.

Future Trends in Transformer Technology

Charlottesville

Advances in transformer technology are shaping the future of energy distribution today. Emerging trends include:

1. Smart Transformers

These devices are integrated with IoT technology to enable real-time monitoring and diagnostics, enhancing efficiency and reliability.

2.

Eco-Friendly Models

Transformers are increasingly designed using biodegradable liquids and sustainable materials to minimize environmental impact.

3.

High-Temperature Superconducting Transformers

These advanced transformers offer improved efficiency and compactness, making them a promising option for future applications.

Commercial and Industrial Electric Transformers are essential to modern infrastructure, enabling efficient and reliable energy distribution across various sectors. By understanding their types, applications, and maintenance requirements, businesses in Charlottesville & Harrisonburg VA can make well-informed decisions that optimize performance and contribute to sustainable energy solutions.

VA COMMERCIAL REPAIR SOLUTIONS SELLS AND INSTALLS:

- NEW INDUSTRIAL AND COMMERCIAL ELECTRIC SURGE PROTECTORS

- NEW AND USED INDUSTRIAL AND COMMERCIAL

ELECTRIC TRANSFORMERS

-ALL TRANSFORMERS HAVE 1 to 5 YEAR EQUIPMENT WARRANTIES-

CALL TODAY TO SCHEDULE A SITE SURVEY FOR AN ELECTRIC TRANSFORMER LOAD CALCULATION

(540) 457-4822 (866) 729-2215