Commercial Ice Maker Cleaning Service

Expert ice machine cleaning services in Charlottesville, VA and surrounding areas to protect your business and keep your ice safe.

VA Commercial Repair Solutions provides comprehensive Commercial Ice Maker Cleaning Charlottesville VA services for businesses in Charlottesville, Harrisonburg, Waynesboro, Staunton,

Fishersville, and Lexington, Virginia. As a S.W.A.M. Certified Company and eVA Certified Provider, we ensure your ice machine meets all health code requirements while producing safe, high-quality ice.

Why Commercial Ice Maker Cleaning Is Critical for Your Business

The FDA classifies ice as a food product, which means your commercial ice machine must adhere to the same safety standards as any other food-producing equipment. Regular professional cleaning isn't just recommended—it's required by law and essential for protecting your customers and business reputation.

We are Certified Ice Maker Distributors and Ice Maker Cleaning Technicians for:

- Manitowoc

- Master-Bilt

- Hoshizaki

- Beverage Air

- Ice-O-Matic

- Turbo Air

PLEASE NOTE: WE DO NOT WORK ON RESIDENTIAL ICE MAKERS or REFRIGERATORS FOR ANY REASON.

Health Code Compliance Requirements

FDA Regulations: According to FDA Food Law 2009 Chapter 4 part 602.11, ice machines must be cleaned "at a frequency specified by the manufacturer," which typically ranges from 2-4 times per year. Some local jurisdictions may require proof of adherence to these cleaning schedules during health inspections.

Legal Consequences: Failure to maintain proper ice machine cleanliness can result in hefty fines. For example, in New York City, a dirty ice machine can cost $250 in fines and 5 violation points. Health code violations can lead to restaurant closures and significant financial penalties.

Health Department Inspections: Ice machines are a primary focus during restaurant health inspections. Violations related to dirty ice machines can result in immediate point deductions, with some infractions causing a five-point reduction on your health score. Mold, slime, or bacterial growth in ice machines has led to numerous restaurant failures and temporary closures across Virginia.

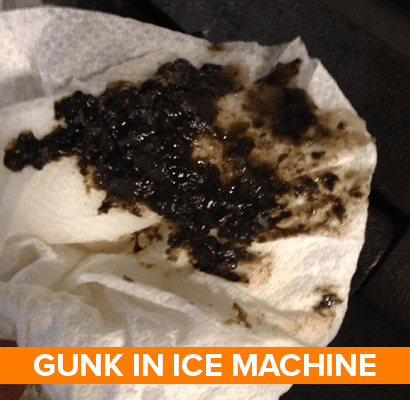

The Hidden Dangers of Neglected Ice Machines

Bacterial and Microbial Growth

Without regular Commercial Ice Maker Cleaning Charlottesville VA, your ice machine becomes a breeding ground for dangerous microorganisms:

- Legionella bacteria: Can cause deadly Legionnaires' disease, as documented in healthcare facilities where patients contracted the illness from contaminated ice

- E. coli and Salmonella: Can grow in warm water that feeds the ice machine

- Gram-negative bacilli and Candida: Studies show these recovered from 100% of ice machine drain pans and over 50% of ice and water chutes

- Pink and brown slime: Visible signs of bacterial "biofilm" that preserves germs in cold temperatures while allowing reproduction in moist environments

Impact on Ice Quality and Business Operations

Contaminated ice machines produce ice that:

- Smells musty, metallic, or foul

- Tastes off or unpleasant

- Appears cloudy or discolored

- Contains visible particles or buildup

A study by the Daily Mail found that one in three food establishments serving dirty ice, and a 2011 Las Vegas study revealed over

70% of ice samples tested positive for coliform bacteria. These quality issues lead to customer complaints, negative reviews, and potential loss of business—all preventable with regular professional cleaning.

Our Comprehensive Commercial Ice Machine Cleaning Checklist

Pre-Cleaning Inspection Protocol

Our certified technicians begin with a thorough Commercial Ice Machine Cleaning Checklist that includes:

Visual Inspection:

- Check for any visible damage or cracks on the machine exterior

- Inspect ice bin for signs of wear, mold, or mildew buildup

- Examine water inlet and drainage system for leaks or blockages

- Look for rust, corrosion, or loose fasteners

- Verify proper grounding and electrical connections

Water System Assessment:

- Verify water system pressure is correct

- Check unit's interior temperature

- Test controls and inspect wiring condition

- Examine water sensors, distributor parts, hoses, and bearings

- Inspect sump or reservoir, valve, and screen components

Ice Quality Evaluation:

- Assess current ice clarity, taste, and odor

- Check for proper ice formation and release

- Document any production irregularities

- Test ice bin sanitation levels

Deep Cleaning and Sanitization Protocol

Step 1: Machine Shutdown and Preparation

- Complete shutdown of ice production

- Disconnect water supply and power source

- Remove and dispose of all existing ice

- Drain all water from the system

Step 2: Component Disassembly and Cleaning

- Remove all accessible components including ice bins, scoops, and contact surfaces

- Disassemble water distribution components, evaporator plates, and internal parts

- Hand-clean all removable parts with warm, soapy water

- Use manufacturer-approved cleaning solutions for specific machine types

Step 3: Scale and Mineral Deposit Removal

- Apply proper descaling chemicals (phosphoric acid solutions) to remove lime, calcium, and mineral deposits

- Circulate cleaning solution through the water system with proper flushing protocols

- Clean evaporator plates to remove scale buildup that impedes heat transfer

- Address any algae or slime growth in water-contact areas

Step 4: Professional Sanitization

- Apply FDA-approved sanitizers specifically designed for ice machines

- Sanitize all water-contact surfaces including bins, scoops, and distribution components

- Use food-safe sanitizing solutions on all surfaces that come in contact with ice

- Allow proper air-drying time before reassembly

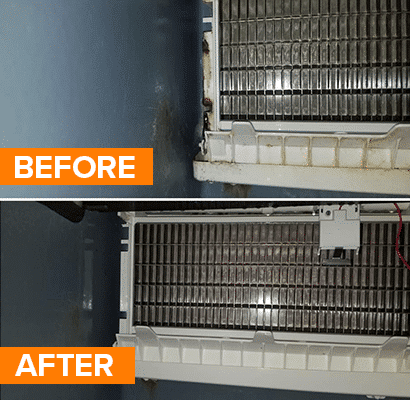

Step 5: Condenser and Filter Maintenance

- Clean condenser coils using non-corrosive cleaners and brushes

- Remove all debris, dust, and grease buildup from air filters

- Replace water filters (recommended every 6 months minimum)

- Pressure clean drain systems and check for proper flow

Step 6: System Testing and Quality Assurance

- Reassemble all components with clean hands and proper alignment

- Reconnect water supply and power source

- Adjust ice level sensors and controls

- Run initial ice production cycles and dispose of first batch

- Observe freeze and harvest times for proper operation

- Verify ice quality meets standards before returning to service

Documentation and Compliance Records

Service Documentation:

- Detailed cleaning checklists with completion verification

- Before and after condition reports

- Water quality test results

- Component replacement records

- Compliance certification for health department inspections

Customized Cleaning Schedules Based on Your Business Needs

High-Volume Operations

Restaurants, bars, and cafeterias with heavy ice usage may require monthly cleaning to prevent rapid bacterial growth and maintain optimal production capacity.

Standard Commercial Establishments

Most businesses benefit from quarterly cleaning services (every 3-4 months), aligning with FDA minimum requirements while ensuring consistent ice quality.

Healthcare and Sensitive Environments

Medical facilities, food processing plants, and other critical environments may need more frequent cleaning based on Joint Commission standards and contamination risk factors.

Environmental Factors Affecting Frequency

- High-heat kitchen environments require more frequent cleaning

- Presence of yeast, sugar, or flour in the area

- Water quality and mineral content in your location

- Machine usage intensity and peak demand periods

Warning Signs Your Ice Machine Needs Immediate Cleaning

Contact VA Commercial Repair Solutions immediately if you notice:

Critical Issues:

- Ice with off-tastes, odors, or metallic flavors

- Visible mold, slime, or discoloration in machine components

- Cloudy, soft, or incomplete ice cubes

- Machine not releasing ice or slow harvest cycles

- Reduced ice production capacity

Performance Degradation:

- Longer freeze or harvest times

- Machine not cycling into harvest mode properly

- Increased energy consumption without explanation

- Shallow or misshapen ice cubes

- Unusual operational noises or vibrations

Benefits of Professional Commercial Ice Maker Cleaning

Regulatory Compliance and Risk Management

- Meet all FDA, CDC, and local health department requirements

- Receive detailed service documentation for inspection records

- Avoid costly violations and potential business closures

- Maintain required manufacturer warranty conditions

- Protect against liability from contaminated ice incidents

Operational Excellence

- Restored ice production capacity and efficiency

- Reduced energy consumption through clean, efficient operation

- Extended equipment lifespan and maximized ROI

- Fewer emergency breakdowns and repairs

- Consistent production of clear, odorless, great-tasting ice

Customer Safety and Business Protection

- Elimination of health risks from contaminated ice

- Protection of business reputation and customer trust

- Prevention of foodborne illness outbreaks

- Compliance with insurance requirements

- Peace of mind for staff and management

Advanced Cleaning Techniques and Equipment

Professional-Grade Cleaning Solutions

- FDA-approved descaling agents: Specifically formulated for ice machine components

- Food-safe sanitizers: No-rinse formulations that kill 99.9% of listed bacteria

- Nickel-safe cleaners: Special formulations for nickel-plated steel components

- Condensate drain cleaners: Natural citrus-based solutions for drain line maintenance

Specialized Equipment and Procedures

- High-pressure spray systems for thorough component cleaning

- Commercial dishwasher processing for detachable components (minimum 80°C final rinse)

- Thermal imaging for heat distribution analysis

- Water quality testing and analysis equipment

Industry-Specific Expertise and Standards

Restaurant and Food Service Compliance

Understanding the unique challenges of commercial kitchen environments:

- Heat and humidity effects on ice machine performance

- Peak demand periods requiring maximum production capacity

- Health code compliance in food service settings

- Integration with existing kitchen workflows and space constraints

Healthcare Facility Requirements

Specialized protocols for medical environments:

- Joint Commission water management plan compliance

- Enhanced hygiene standards for patient care ice

- Critical control point documentation and monitoring

- Specialized cleaning frequencies for high-risk areas

Hospitality and Entertainment Standards

Meeting the demands of hotels, bars, and venues:

- High-capacity production for peak occupancy periods

- Premium ice quality for beverage service excellence

- Aesthetic considerations for customer-facing equipment

- Minimal service disruption during operating hours

Service Areas and Flexible Scheduling

We provide Commercial Ice Maker Cleaning Charlottesville VA services throughout Central Virginia:

Primary Service Areas:

- Charlottesville: Complete coverage including UVA campus and downtown business district

- Harrisonburg: Full service including JMU area and surrounding commercial zones

- Waynesboro: Industrial and commercial facilities with specialized protocols

- Staunton: Historic downtown and modern commercial areas

- Fishersville: Business parks and commercial developments

- Lexington: Tourism, hospitality, and educational facility services

Convenient Service Options

- Scheduled maintenance programs: Quarterly, bi-annual, or custom frequencies

- Emergency cleaning services: Rapid response for health code issues

- After-hours appointments: Minimize business disruption with flexible timing

- Seasonal preparation: Deep cleaning before peak usage periods

Investment in Long-Term Equipment Health

Preventive Maintenance Integration

Our cleaning services work together with Commercial Ice Maker preventive maintenance:

- Early identification of potential mechanical issues

- Optimization of operational settings and controls

- Water filtration system evaluation and recommendations

- Energy efficiency assessments and improvements

Cost-Benefit Analysis

Regular professional cleaning provides measurable returns:

- Avoided downtime costs: Preventing emergency breakdowns during peak business

- Energy savings: Clean machines operate 15-20% more efficiently

- Extended lifespan: Proper maintenance can double equipment life expectancy

- Regulatory protection: Avoiding fines and business interruption costs

Get Started with Professional Ice Machine Cleaning

Don't risk your business reputation, customer safety, or regulatory compliance with inadequate ice machine maintenance. Commercial Ice Maker Cleaning Charlottesville VA services from VA Commercial Repair Solutions ensure your ice is always safe, clean, and refreshing.

Why Choose VA Commercial Repair Solutions?

- S.W.A.M. Certified Company with proven expertise and industry recognition

- eVA Certified Provider meeting government standards and requirements

- Exclusive commercial focus – we service only commercial ice makers, no residential units

- Comprehensive regional coverage across Central Virginia

- Emergency response capability when you need it most

- Detailed documentation for compliance and warranty protection

Do you have a Commercial Ice Machine Cleaning Checklist? If not, you really should. The FDA mandates ice be stored and handled by the same standards as food. This means that ice machines must be cleaned and sanitized at least 2-4 times per year according to most manufacturers. Some jurisdictions require you to prove that you do adhere to the manufacturer's recommendations as they apply to cleanliness and sanitization.

Contact us today to schedule your professional ice machine cleaning service and protect your business with reliable, compliant ice production all year round. Our experienced professional technicians will keep your Commercial Ice Cube Maker working for many years after other technicians have told you to replace it.